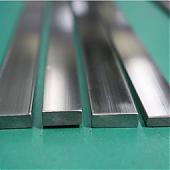

Stainless Steel Bar Suppliers

316L stainless steel rod: 316 stainless steel containing molybdenum and low carbon content, and chemical industries in the ocean environment point of corrosion resistance substantially better than the 304 stainless steel! (316L low carbon, 316N nitrogen-containing high strength and high sulfur content 316F stainless steel, free cutting stainless steel.

304L stainless steel rod: 304 as a low-carbon steel, in general, corrosion resistance and 304 similar, but after welding or eliminate stress, its excellent corrosion resistance to the grain boundaries, in the case without heat treatment, but can also maintain good corrosion resistance.

304 stainless steel rod: have good corrosion resistance, heat resistance, low temperature strength and mechanical properties, stamping, bending and other thermal processing, and no heat treatment hardening. Usage: tableware, cabinets, boilers, auto parts, medical equipment, building materials, food industry (temperature -196 ° C-700 ° C).

310S stainless steel round bar: The main features are: high temperature, general use of the boiler, automobile exhaust pipes Other performance in general.

303 stainless steel rod: by adding a small amount of sulfur and phosphorus to more than 304 cutting, and 304 with other similar properties.

302 stainless steel rod: 302 stainless steel rods are widely used in auto parts, aviation, aerospace hardware tools, chemical industry. As follows: crafts, bearings, slip flower, medical equipment, electrical appliances. Features: 302 stainless austenitic steel ball, with close to 304, but 302 higher hardness number, HRC≤28, with good rust and corrosion protection.

301 stainless steel rod: scalability, for molding products. It can also be rapidly hardened by machining. Good weldability. Abrasion resistance and fatigue strength than 304 stainless steel.

202 stainless steel round bar: are chromium - nickel - manganese austenitic stainless steel, 201 stainless steel is superior.

201 stainless steel round bar: are chromium - nickel - manganese austenitic stainless steel, magnetic low.

410 stainless steel rod: martensitic (high-strength chrome steel), good wear resistance, corrosion resistance is poor.

420 stainless steel rod: "cutting class" martensitic steel, similar to Brandt's first high-chromium stainless steel this. Also used in surgical tools, you can do very light.

430 stainless steel rod: ferritic stainless steel, decorative, such as for car accessories. Good shape, but heat resistance and corrosion resistance worse.

If you have any required for the stainless steel round bar please feel free to contact Jawaysteel at www.jawaysteel.com.

Related Products