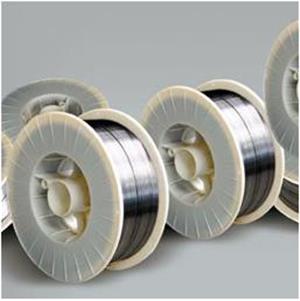

Prime Quality 316L Stainless Steel Welding Wire

SS316L welding wire (1.4404, "L" means "low carbon") is offering a easier to weld stainless steel due to its low carbon content and results in improved corrosion resistance after welding. This stainless steel alloy offers better corrosion resistance than AISI 304L due to the addition of 2-3% Molybdenum. The 316LSi welding wire distinguishes itself due to the higher hardness (tensile strength of the wire >1400 N/mm2) and that offers a remarkable stable arc especially when welding with impulse arc on thin stainless steel sheets. Also a complete different surface treatment makes this wire suitable for the Hotwire Tig process without intermediate cleaning between the layers.

316L deposit is an austenitic stainless steel w/controlled ferrite for molybdenum alloy stainless and is used to join types 316, 316L, CF-8M and CF-3M. It has better pitting resistance than molybdenum-free stainless.Grade 316L, the low carbon version of 316 and is insusceptible to sensitization. Thus, it is expansively utilized in heavy gauge welded components (over about 6mm).

Alloy ER 316L is primarily used for welding low carbon molybdenum-bearing austenitic alloys. This filler metal has the same analysis as ER316, except that the carbon content is limited to a maximum of 0.03% in order to reduce the possibility of formation of intergranular carbide precipitation. This low carbon alloy is not as strong at elevated temperatures as ER 316H

Specifications

AWS 5.9

ASME SFA 5.9

AWS ER 316/ ER 316L

UNS S31683

Application and Usage:

Stainless steel welding wire can be used in the welding operation and flow-ability of Cr elements.It is applicable for the Non-Magnetic steel, High Mn steel, Hardended Abrasion resistance steel and the super low carbon and stainless steel profiled metal’s welding.

Factory direct sales prime quality 316L stainless steel welding wire,welcome your inquiry.

Related Products

Factory Introduction

Cold-Rolled vs. Hot-Rolled Stainless Steel Sheets

Jaway Steel: Your Premier Partner for Premium Stainless Steel Products