how to choose stainless steel metal hose

1, look at the appearance, good stainless steel to form a metal hose color bright, not black

2, to confirm the bellows, holding the finished product under the feeling of bending, good stainless steel material flexibility is good.

3, steel wire mesh on the arrangement of the wire neatly, not the wire, which is the test of metal hose production equipment.

4, the easiest way to use a magnet to suck, the real stainless steel is not sucked.

Stainless steel metal hose stainless steel named refers to the resistance to air, steam, water and other weak corrosive media and acid, alkali, salt and other chemical erosion medium corrosion of steel, also known as stainless acid just. Daily applications, often weak corrosion corrosive steel corrosion of steel known as stainless steel, and chemical resistance to corrosion of steel known as acid-resistant steel.

Because of the difference in chemical composition between the two, the former is not necessarily resistant to chemical corrosion, while the latter are generally have a stainless steel. Stainless steel metal hose The corrosion resistance of stainless steel depends on the alloying elements contained in the steel. Stainless steel base alloy elements are nickel, molybdenum, titanium, niobium, copper, nitrogen, etc., to meet the various uses of stainless steel structure and performance requirements.

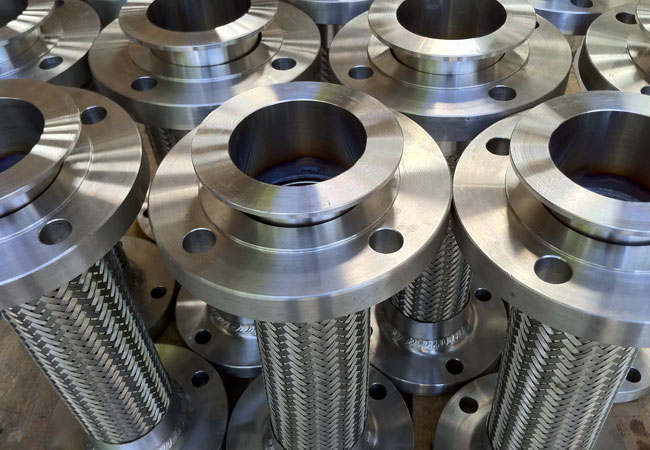

Metal hose structure is the internal bellows, outside the woven steel mesh sets or steel (large diameter multi-purpose), both ends of the joint or flange form of the composition of the connection!

Function: to reduce the installation of the pipeline stress, compensation for the rated position of the pipeline to move, to absorb the vibration of the pipeline system.

Stainless steel metal hose selection points:

(1) size hose nominal diameter, the choice of joint type (mainly flange connection, threaded connection, quick connector connection) and metal hose size, hose length.

(2) pressure according to the actual working pressure of the hose, and then check the corrugated metal hose nominal diameter and pressure gauge, decide whether to use stainless steel mesh sets of metal hoses.

(3) media hose in the transmission of the chemical properties of the media, according to the hose material corrosion resistance, determine the hose parts of the material.

(4) temperature The working temperature and range of the medium in the hose; the ambient temperature at which the hose is operating. At high temperatures, the working pressure temperature correction factor at the high temperature of the metal hose shall be determined to determine the temperature after the temperature correction to determine the correct pressure rating.

(5) Status When using the hose, refer to the correct use and installation method of the metal hose and the optimum length of the hose during settlement compensation. The length of the various movement of the hose calculation and the minimum number of bending the hose and the minimum bending radius and other factors, the parameters of the correct selection of hose length, and the correct installation.

Related Products

Factory Introduction

Cold-Rolled vs. Hot-Rolled Stainless Steel Sheets

Jaway Steel: Your Premier Partner for Premium Stainless Steel Products