high production process of 303 stainless steel tube

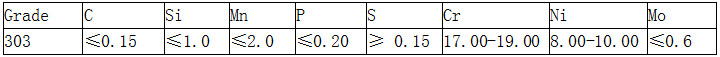

Chemial composition of 303 stainless steel tube:

mechanical property of 303 stainless steel tube:

tensile strength:≥520 MPA

Yield strength:≥205 MPA

Elongation:≥40%

Hardness:hb≤187hb hrc≤90hrb hv≤200hv

Production process of 303 stainless steel tube:

1)Forming:The forming part of the steel strip enters the pipe making machine to form a semi open arc of the required external diameter pipe through the gradual change of the pipe mould in the process of the front line.

2)Welding:Automatic welding by argon arc welding machine.

3)Setting and cutting:After the welding of the pipe after the grinding of the weld through the stereotypes of the pipe type integer and diameter, through the online automatic cutting equipment to cut to the required length.

4)Polish:After a flat profile through the circle or a square tube polishing machine on the surface of the polishing, the tube surface finish up to more than 500.

303 stainless steel is widely used in petroleum, electronics, chemical, pharmaceutical, textile, food, machinery, construction, nuclear power, aerospace, military and other industries.

Related Products

Factory Introduction

Cold-Rolled vs. Hot-Rolled Stainless Steel Sheets

Jaway Steel: Your Premier Partner for Premium Stainless Steel Products