SS316L welded polished pipe

Jawaysteel Co., Ltd., is a professional manufacturer and global exporter specializing in SS316L welded polished pipe. Stainless steel 316L pipe and tubing is offen devided into welded pipe and seamless pipe. As we know that SS316L pipe are known for excellent resistance to grain boundary corrosion.

SS316 welded polished pipe is often compared with SS316L pipe, what is the difference between them:

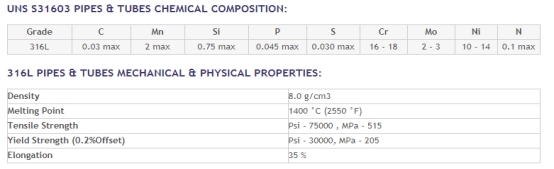

316 and 316L SS316L welded polished pipe are stainless steelsmaterial containing molybdenum. The content of molybdenum in 316L stainless steel is slightly higher than that in 316 stainless steel pipe. Due to the molybdenum in steel, the overall performance of this steel is better than 310 and 304 stainless steel. SS316 stainless steel has good chloride corrosion properties, so it is usually used in marine environments. SS316L stainless steel pipe has a maximum carbon content of 0.03, which can be used in applications that cannot be annealed after welding and require maximum corrosion resistance.

Heat resistance:

In intermittent use below 1600 degrees and continuous use below 1700 degrees, 316 stainless steel pipe has good oxidation resistance. In the range of 800-1575 degrees, it is best not to continuously act on 316 stainless steel pipe, but when 316 stainless steel pipe is continuously used outside this temperature range, the stainless steel has good heat resistance. 316L stainless steel pipe has better resistance to carbide precipitation than 316 stainless steel pipe, and the above temperature range can be used.

Welding:

SS316 stainless steel pipe has good welding performance. All standard welding methods can be used for welding. the welded section of 316 stainless steel pipe needs to be annealed after welding. If 316L stainless steel pipe is used, post-weld annealing treatment is not required.

Related Products

Factory Introduction

Cold-Rolled vs. Hot-Rolled Stainless Steel Sheets

Jaway Steel: Your Premier Partner for Premium Stainless Steel Products