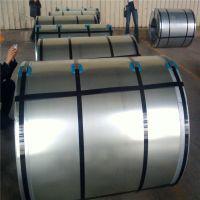

Hot Dip Galvanized Steel Coil

Hot dip galvanized steel coil is to make molten metal react with iron matrix to produce alloy layer, so that the substrate and the coating are combined. Hot-dip galvanizing is to pickle the steel parts, in order to remove the iron oxide on the surface of the steel parts, after pickling, through ammonium chloride or zinc chloride solution or ammonium chloride and zinc chloride mixed solution tank for cleaning, and then into the hot-dip bath. Hot dip galvanized steel coil has the advantages of uniform coating, strong adhesion and long service life.

Hot Dip Galvanized steel coil is used to immerse the thin steel sheet into the molten zinc bath to make the surface adhere to a thin sheet of zinc. At present, it is mainly produced by continuous galvanizing process, that is to say, continuous dipping of coiled steel sheet into galvanized steel sheet in a galvanized bath with melting zinc, and alloying galvanized steel sheet. This steel plate is also made by hot-dip method, but immediately after the trough, it is heated to about 500 degrees Celsius to form zinc and iron alloy coating. This Hot Dip Galvanized steel coil has good coating adhesion and weldability.

Hot Dip Galvanized steel coil is mainly used in the fields of architecture, household appliances, automobiles, containers, transportation and family businesses and so on, especially in areas of steel structure construction, automobile manufacturing, steel warehouse manufacturing and other industries. Hot Dip Galvanized steel coil is characterized by strong corrosion resistance, good surface quality, benefit from deep processing, economic and practical applications, etc.

Jaway Steel is an original manufacturer specializes for stainless steel, hot dip galvanized, steel and alloy steel plate, sheet, bar, tube etc. If you need more details about our Hot Dip Galvanized steel coil or the latest price, please contact us freely: email address: 825@jawaysteel.com.

Related Products

Factory Introduction

Cold-Rolled vs. Hot-Rolled Stainless Steel Sheets

Jaway Steel: Your Premier Partner for Premium Stainless Steel Products