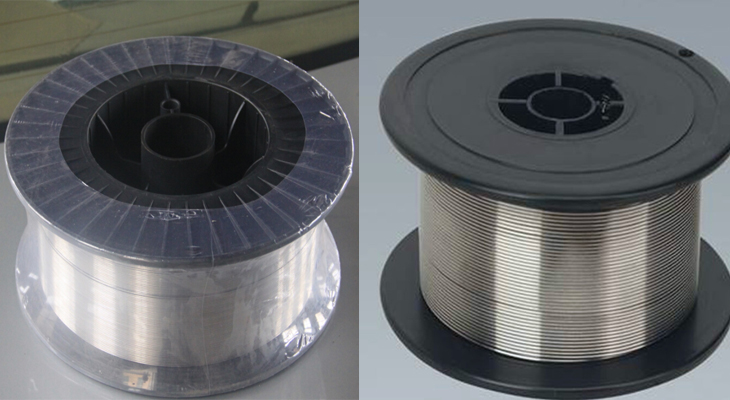

316L Stainless Steel TIG Welding Wire

TIG welding wire is tungsten argon arc welding with welding wire.

Common types: low carbon steel; Low alloy steel; Stainless steel; Copper and copper alloy; Aluminium and aluminium alloy of metal, there are corresponding to the material of the argon arc welding wire type.

TIG welding wire(tungsten inert gas arc welding) is a welding method of YISHION Ar as protective gas and tungsten electrode as electrode. TIG welding wire is supplied in straight strip supply at a certain length (usually LM).316L Stainless Steel TIG Welding Wire is a common type.

Requirement of 316L Stainless Steel TIG Welding Wire

Protection gas flow requirement: when the welding current is between 100-200A, it is 7-12L/min; when welding current is between 200-300A, 12-15L/min is appropriate.

Length of tungsten pole relative to the nozzle should be as short as possible, the arc length should be arc length control in general for 1-4mm

When the wind speed is greater than 1.0m/s should be used to pay attention to ventilation, wind proof measures; to avoid operator injury;

When welding welding impurity strict cleaning oil, rust, moisture.

The DC power supply is recommended dropping characteristic, tungsten cathode.

In the welding of low alloy steel is more than 1.25%Cr, the back also should be protected.

Protective gas for welding wire

1)Argon (Ar):Density than air, thermal conductivity and heat capacity ratio of air is small, has good characteristics of arc stability. With Ar protection of MIG welding, metal wire axial jet transition easily is stable, small splash. For welding to protect the purity of the gas should reach 99.9 ~ 99.999%. Because it is a by-product of fractional distillation of liquid air, so the harmful impurities is oxygen, nitrogen and water vapor.

2)Helium(He):The ionization energy of helium is higher, so it is difficult to lead arc when welding, the arc ignition characteristic is poor, and the arc voltage of helium arc is high, which makes the arc have larger electric power, higher arc temperature and greater heat transfer to welding. Because the density is smaller than the air, therefore the flow must be big. Expensive.

3)Hydrogen (H2). With small density and high thermal conductivity, it can absorb a large amount of decomposition heat, so it has a strong cooling effect on the arc.

4)Mixed gas. Mixed gas for fine droplet, reduce spatter and improve the arc stability, improve the penetration and improve the arc temperature.Including Ar + He,Ar + H2,

Related Products

Factory Introduction

Cold-Rolled vs. Hot-Rolled Stainless Steel Sheets

Jaway Steel: Your Premier Partner for Premium Stainless Steel Products