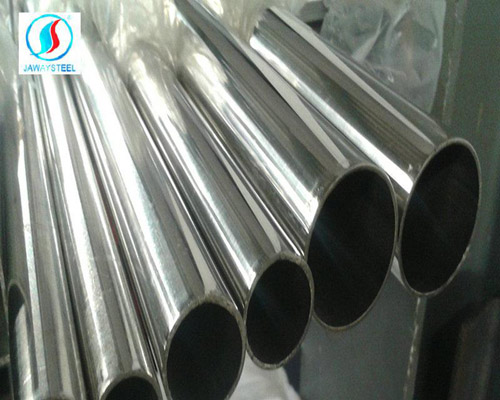

309 stainless steel pipe

309/309S is applied under high temperature. 309/309S is commonly used in some equipment, such as incinerators, furnaces, kiln, annealing and carburizing tanks, combustion chambers, salt basins, hot wells, gas turbines, sterilizers and some equipment used to treat sulphite liquors.

Alloy 309S is best known for its high temperature properties. This alloy is resistant to heat up to 2000 Fahrenheit, especially when oxidation resistance is required.

In our inventory, 309 and 310 are representative of common high-temperature stainless steel grades. Its high nickel and chromium content and coarse crystal structure can have the following effects:

a.Improves cyclic oxidation resistance

b.Increase the vulcanization resistance

c.Better high temperature strength

d.Improve resistance to intergranular corrosion

The 309S (UNS S30908) is a low carbon alloy that is widely used. 309H (UNS S30909) contains high carbon, which enhances the creep resistance of the material.

In most cases, the intercrystalline grain size and carbon content plates meet the 309H and 309S requirements. When heated to 1202–1742°F (650–950°C) sigma precipitated. Annealing at 2012°C (2102°C) 1100°C (1150°C) will restore a certain degree of toughness.

Alloy 309 can be welded and processed through standard shop processes.

All Type 309 stainless steel has the same chemical composition, which includes:

Fe 60%

Cr 23%

Ni 14%

Mn 2%

Si 1%

C 0.20%

P 0.045%

S 0.030%

Continental Steel is able to supply Type 309 Stainless Steel in a variety of shapes and sizes including sheet, coil, plate, bar, and more. All of the Type 309 Stainless Steel supplied meets or exceeds leading industry standards like those from ASTM and ASME.

Related Products

Factory Introduction

Cold-Rolled vs. Hot-Rolled Stainless Steel Sheets

Jaway Steel: Your Premier Partner for Premium Stainless Steel Products